Next Day Delivery Available

Common Washing Machine Problems

If you have a problem with your washing machine we'll help you identify the fault and give you advice on how to repair it.

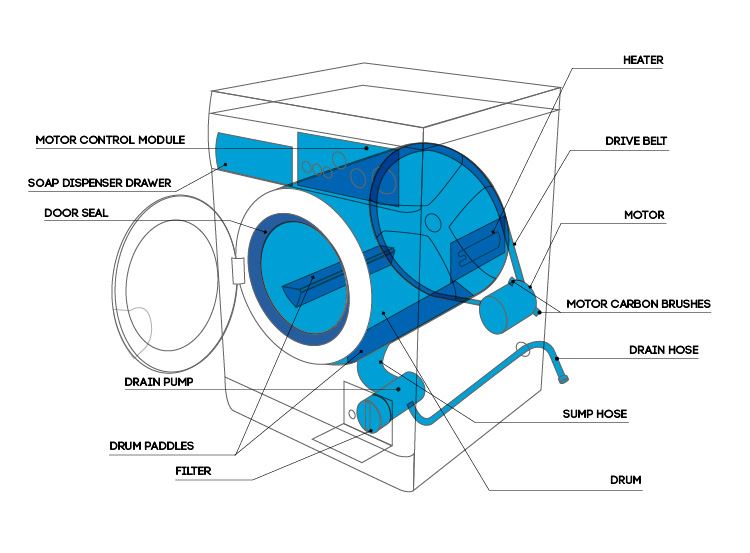

Anatomy of a washing machine

Before diving into diagnosing your specific fault, it's worth taking a minute to study the anatomy of a washing machine and familiarise yourself with the inner components and their location; it will help fault finding and repair.

For example, an unusual noise coming from the lower right area of the washing machine would suggest that something is stuck in the pump filter; perhaps a foreign object such as a coin is catching on the pump implellor. A leak from the back right hand corner of your washing machine could mean a problem with the waste hose, and would be a good place to start looking.

Of course not all washing machines are put together in exactly the same way, but the laws of physics and mechanical engineering means that they all follow a similar theme.

The pump will always be found at the bottom of the machine because they are gravity fed by design. On a belt driven washing machine (99% of all washing machines) the belt and pulley will be located at the rear of the tub. And, Just below, you will find the motor, that drives the drum via the belt. Any electronics will tend to be up above the water line for obvious reasons. Once you begin to look at the inner workings of a washing machine it will quickly become logical why components have been fitted where they are!

How A Washing Machine Works

How A Washing Machine Works

Watch our DIY repair video on how a washing machine works

Why Won't My Washing Machine Turn On?

This fault can leave you wondering if your washing machine is beyond economical repair; when you turn your washing machine on it does nothing!

More often than not the problem is easily fixed at no cost, or by replacing an inexpensive part.

Check the power to the washing machine

Don't skip this part ...

Remember that the power starts at the consumer unit (fuse box); make sure that a fuse hasn't tripped.

Next, check the plug socket; the best way to confirm that there isn't a fault with the plug socket is to plug another electrical appliance such as the kettle to see if it boils as it should.

If all is ok with the consumer unit and the socket next you now need to confirm the wiring to the plug looks good and there are no kinks or breaks in the wire, and check that the fuse in the plug is ok.

Check the washing machine door

Again, often overlooked but it's a simple mistake to make. Check your washing machine door is closed and closed properly. All washing machines have what's known as a door interlock. It is designed to stop the door from being opened when the machine is switched on, and unless the door of your washing machine is fully closed and latched, it won’t start.

Possible faulty components that cause a washing machine not to turn on

Faulty Door Interlock (most likely fault)

As mentioned above, washing machines won’t start if the door isn’t properly locked (or isn’t registered by the machine as correctly locked). As a result, a faulty door interlock could prevent the machine from starting. Watch the following video for a step by step guide on:

How To Replace A Faulty Door Interlock?

How To Replace A Faulty Door Interlock?

Watch our DIY repair video on how to replace your faulty door interlock

Faulty On/Off Switch (relatively rare fault)

It is possible that the on/off switch is faulty and will need replacing.

Faulty Module Circuit Board (relatively rare fault)

A faulty module circuit board could prevent your washing machine from turning on – in this case; you will need to get it professionally repaired. This is the least likely component to fail, but they do fail from time to time.

Faulty Suppressor (least likely fault)

The interference suppressor is normally situated internally at the point where the power lead enters the washing machine. It is designed to eliminate interference between electrical items. If this 'blows' then your washing machine will not work at all.

Why is My Washing Machine not filling?

This fault can appear similar to that in the above section, 'Why won't my washing machine turn on'. With this fault, power will be getting to the valves, but water won't be entering the washing machine.

Check the washing machine inlet hose/s

By far the most common cause of a washing machine not filling is kinked inlet hoses. You will need to gain access to the rear of the washing machine and check that the hoses aren't trapped or kinked.

Check the water taps (plumbing)

With access to the rear of the washing machine, you can now check that the water taps are turned on. If you suspect a problem with your water supply, turn off the water taps, and disconnect the inlet hoses from the washing machine. Place the inlet hoses in a bucket and then turn on the water taps. You will want to see water to flow out under pressure to confirm that the water supply is ok.

Check washing machine inlet valve filters

If your washing machine is filling, but very slowly, check the inlet valve filters aren't clogged with debris. Turn off the water taps, disconnect the hose/s from the washing machine, and the valve filters will be visible. They can be removed with a pair of long nose pliers and cleaned if necessary.

Possible faulty components that cause a washing machine not to fill

Faulty Inlet Hose (Most likely fault)

If you identify an inlet hose to be kinked, then it will most likely need to be replaced. If you don't, it will quickly become kinked again once the washing machine is back in position.

Faulty Inlet Valves (Likely fault)

Check at the back of the machine where the inlet hose screws on to the inlet valve. If the water supply is ok and you can hear a humming noise from the water inlet valve/s then it is likely they are faulty and will need replacing.

How To Replace A Faulty Inlet Valve?

How To Replace A Faulty Inlet Valve?

Watch our DIY repair video on how to replace a washing machine inlet valve

Why is my washing machine filling when it's turned off

This fault can be disastrous and requires immediate attention. If you are lucky you will catch it early; you will come to load your washing machine with clothes and notice that the drum has water in it. The problem will lie with the washing machine inlet valve, and you should replace it ASAP. While waiting for the replacement part ensure that you turn the taps off when the washing machine is not in use.

How to replace a faulty water inlet valve

How to replace a faulty water inlet valve

Watch our DIY repair video on how to replace a faulty water inlet valve

Why Won't My Washing Machine Drum Spin or Turn

You'll probably first notice this fault when you return to your washing machine to remove a load of washing and the clothes inside are soaking wet. The cause is simple; the washing machine has completed it's program without spinning the clothes at the end.

Check the load

First, you should check the size of the load that is in the washing machine. Too little clothes in a washing machine can be just as problematic as too many. There needs to be just the right amount of clothes so that when the washing machine spins, they are evenly distributed around the drum ensuring balance. The control module will detect a drum that is out of balance, and the washing machine will stop to prevent any damage occurring. Just adjust the size of your load and select a spin cycle again. If your washing machine spins without any problem, then it was 'out of balance' that caused the problem.

Check the washing machine belt

It is possible that the washing machine belt has worked its way off the motor/pully. A simple check is to open the door and turn the drum with your hand. If the drum rotates VERY freely without any resistance, then it is likely that the belt has become detached.

If you can feel some resistance, which is the belt turning the motor, then the belt is still correct in place

Check the wash cycle

Having followed the steps above it is now likely that the fault isn't just affecting the spin cycle. Select your regular wash cycle and switch on the machine. It should fill up with water, and the drum should eventually start turning back and forth washing machine the clothes. If the drum sits idle, then the fault will likely be the motor carbon brushes, the motor, or the motor control module.

Possible faulty components that cause a washing machine not to turn or spin

Broken or snapped belt (Most likely)

As mentioned above, if the washing machine drum rotates by hand VERY freely then the belt is likely to be the cause of the problem.

How to replace the belt on a washing machine.

How to replace the belt on a washing machine.

Watch our DIY repair video on how to replace the belt on a washing machine.

Faulty or worn washing machine carbon brushes

Carbon brushes are in constant contact with the moving part of the motor, so they get worn down over time and will eventually need replacing.

How to replace carbon brushes on a washing machine

Watch our DIY repair video on how to replace carbon brushes on a washing machine.

Faulty motor control module (least likely)

A defective module circuit board can prevent the motor from turning the drum. If suspected then you should seek the services of a trained appliance repair specialist.

Faulty motor (uncommon)

Faults with the motor are uncommon, however they do occur. If suspected then you should seek the services of a trained appliance repair specialist.

Why is My Washing Machine Leaking?

A washing machine that has sprung a leak is a fault that ranges in severity, from a minor dribble to an all-out flood. Usually, leaks can be fixed yourself at little or no cost; you just need to have a methodical approach to finding the source.

Start looking on the outside of the washing machine

Before you start removing the washing machine lid and rear panel first take some time to see if there are signs of water on the outside of the washing machine.

Check the water inlet taps and hoses

The area to start your investigation is at the rear of the washing machine where the water inlet hoses are attached. With the washing machine running check for water at each end of the inlet hoses.

Washing machine waste pipe blocked?

A common problem in hard water areas where a build-up of limescale can cause blockages in your waste pipe restricting the flow of water to the drain. Water will back up and overflow the waste pipe causing flooding. Check the wall area around the waste pipe for signs of water.

Check the soap dispenser

A build-up of powder detergent in the hose that runs from the soap dispenser to the tub will eventually cause a blockage and water would back up and flood from the soap dispenser drawer.

Check the washing machine door

A common area for leaks is the washing machine door. If it appears that water is coming from the door, check the door seal for signs of damage or perishing.

Check the door glass; a build-up of limescale on the glass will mean that the door isn’t forming a seal causing water to escape.

Check the washing machine filter

If your washing machine has a removable filter, you will almost certainly find it at the front bottom of your washing machine. Sometimes it can be hidden behind the plinth. A damaged or perished filter seal will be enough to cause a leak in this area.

Leaks from inside the washing machine

Once you have ruled out the leak is coming from outside of the washing machine it will be necessary to investigate the internal hoses and components. First, it is a good idea to try and understand the approximate location of the leak. To do this, you can spread some newspaper or cardboard underneath the washing machine, and then turn it on. The position of the water leak will now be visible and give you a good idea of where to investigate first.

Check the pump and associated hoses

Leaks from the washing machine pump are relatively rare. However, a build of limescale can cause hoses and seals to perish.

Check the internal hoses and plastic components

Any component that is rubber or plastic has the potential to break down and cause a leak. You will typically see a tell-tale sign that water has leaked around an area.

Nowadays washing machine tubs are constructed of plastic, not metal, and it is not uncommon for a foreign object, such as a coin, to get caught up between the drum and the tub sheering part of the plastic moulding.

Possible faulty components that cause a washing machine to leak

Perished or damaged washing machine door seal

Washing machine door seals are liable to become damaged, or perish, over time.

How to replace a washing machine door seal

How to replace a washing machine door seal

Watch our DIY repair video on how to replace a washing machine door seal

Damaged filter or filter seal

Carbon brushes are in constant contact with the moving part of the motor, so they get worn down over time and will eventually need replacing.

How to replace or clean the filter on a washing machine

Watch our DIY repair video on how to clean and replace the filter on a washing machine

Damaged washing machine drain hose

The plastic drain hose can become damaged if kinked during the installation of the washing machine. It has also been known for mice to chew a hole in the washing machine drain hose.

Damaged washing machine inlet hose

Failure of the water inlet hoses can occur. The rubber 'O' seal found at both ends of the hose can also fail and cause leaks.

Damaged internal hoses

Any rubber hose inside the washing machine can fail over time.

Damage to plastic tubs

Can occur if a foreign object such as a coin passes through the washing machine during a cycle.

Why is my washing machine making a noise?

Whether it’s a grinding noise, a knocking noise, or an intermittent noise you will want to investigate and repair the problem sooner rather than later. Leaving it can lead to a much bigger problem to fix.

Noise from your washing machine pump

Noise coming from the pump area of your washing machine will typically mean that a foreign object, such as a coin, will have passed through the system and be caught in the filter. Most pumps fitted to washing machines in recent years are an integral part of the filter housing (note: some washing machines don’t have filters at all). Small foreign objects can pass into the filter by slipping through the gap between the outer tub and the rotating drum. Items such as pebbles, coins and small screws or nails - to name a few.

These items can then pass from the filter into the pump chamber where the pump’s impeller will ‘whiz’ the object around the chamber making a loud rattling noise - think blender, putting a screw in the blender’s container would give a similar effect.

The pump’s impeller rotates at a tremendous speed to expel the water from your washing machine. Consequently, there is strain put on this small part. The impeller will also have to cope with pushing small pieces of debris out along with the water. Mostly, the impeller will deal with what it is expected to do, but on occasions, it may come loose and begin to make a noise and is likely to break away all together eventually.

Noise from the drum area of the washing machine

Grinding noise from the drum during the wash and spin cycles usually suggest that the drum bearings have worn. To check, turn the drum back and forth; movement should be smooth and easy with very little resistance or noise. If you can hear or feel grinding then this is confirmation that your washing machine bearings have indeed worn.

If you suspect the drum bearings to be a problem, another quick way to indicate this is to look at the floor below your washing machine. If you find a black or brown patch, then remove the back cover of your washing machine and inspect the area just below the centre of your drum pulley. If the same coloured marks are streaking down the rear of the outer tub, this indicates that the drum bearing seal has worn or perished letting water enter and destroy the bearings.

Drum Shaft

The rotating drum is held in its position by a component called a drum support shaft or drum support spider consisting of three metal alloy arms and a steel shaft which protrudes through the drum bearings enabling the drum to rotate.

The arms attach to the rear of the drum at the points where the baffles are in place. Looking through the door to the back of the drum, you will observe three pressed shapes radiating from the centre to each baffle point - that’s where you will find the drum support shaft.

These shafts do shear, and the impact is immediate, the consequent noise is quite alarming for the simple fact that it is so sudden. Just inside the door opening, hold the tub down with your fingers at the 6 o’clock, rotate the drum, so a baffle is at 12 o’clock, then push up the drum to see if you can detect a spongy movement of the drum.

This movement may be evident for one or maybe two arms. Another indication is when the drum rotates you might observe an apparent misalignment between the rotating drum and the static outer tub.

Foreign body caught between drum and tub

Another noise that is not uncommon is a coin or some other foreign object that has found it’s way between the outer tub and the drum. The unusual sound will likely be heard during the spin cycle when water is being forced out of the clothes and whipping up the foreign object/s. Bra wires are a favourite! Over time they work their way out of the garment and fit comfortably through the holes in the drum. They will make a distinct tinny rattle as they scrape against the rotating drum.

Noise from the motor

Worn motor bearings while less likely are possible; they are more difficult to isolate for the untrained ear as the sound is distinct.

If there is noticeable wear of the motor bearings, then one can attempt to distinguish between these or drum bearing noise by removing the back panel and taking the belt off the motor/drum pulleys. Rotate the drum to see if any sound indicating worn bearings is detected, if not, now rotate motor pulley for any signs of noticeable wear and noise.

Miscellaneous washing machine noise

Loose tub weight:

If you hear your washing machine begin to knock and you also find grey dust appearing under or around your washing machine, stop using it immediately.

There are usually two counterweights inside your washing machine designed to help balance the tub/drum during use. You will find one on top of the tub, and one on the lower front of the tub.

Damage to either counterweight can cause severe damage, the tub weights are hefty and if they become loose or cracked they will rip away from the tub during spin cycle usually destroying their brackets and rendering your machine beyond economic repair.

Transit bolts or packaging not removed

If your machine is new and it begins to vibrate excessively to the point of moving, then consider checking that you, or the person that installed the washing machine, have removed the transit bolts and any internal packaging.

Check underneath your machine as often large pieces of polystyrene are placed there as part of the packaging to protect the motor and can easily be overlooked during installation.

Possible faulty components that cause washing machine noise

Damaged pump

Damage to the washing machine pump by foreign objects such as coins is a common problem.

How to replace a washing machine pump

How to replace a washing machine pump

Watch our DIY repair video on how to replace a washing machine pump

Worn washing machine drum bearings

Depending on use, washing machine bearings won't last forever. In many modern washing machines drum bearings are now encased on sealed tubs and cannot be replaced. In these cases the tub and drum would be replaced as one unit.

Damaged drum shaft spider

Although uncommon, drum shaft spiders do break down from time to time.

Worn motor

Noise because of a worn motor is a relatively uncommon fault.

Counterweights

Counterweights are constructed of concrete and can develope cracks due to vibration.

Why won’t my washing machine door open

Firstly, don’t be tempted to force the door open!

Check if the washing machine is still full of water

If there is water in the drum, the washing machine door will remain locked. Follow our step by step video guide to solving this problem:

how to drain the water from the machine and get the door open

how to drain the water from the machine and get the door open

Watch our DIY repair video on how to drain your washing machine when the door won't open

Broken washing machine door handle

Broken door handles are a common fault. If there is less resistance than usual when you pull or squeeze the handle to open the door, then the part of the door handle that moves the latch will have broken away.

Child lock engaged

Modern machines now have their wash programs selected electronically via a control module or power board depending on how the manufacturer describes the component. More often they have a child lock function available to the user. It is easy to select by mistake and is usually indicated by a lit ‘key’ symbol if your machine has a console display or a key symbol on your machine’s console panel with an indicator light adjacent to it. Refer to your instructions for your washing machine.

Possible faulty components that cause a washing machine door not to open

Broken door handle

Washing machine door handles are plastic and prone to wear and tear.

How to replace a washing machine door handle

How to replace a washing machine door handle

Watch our DIY repair video on replacing the door handle on a washing machine

Faulty door interlock

The washing machine door interlock ensures that the door cannot be opened during a wash cycle.

Why is my washing machine smelly & door seal black & mouldy

Mouldy washing machine door seals are a bi-product of our attempt to reduce the carbon footprint, and rightly so! If we can save the world from human destruction, who cares about a smelly, mouldy washing machine door seal? Well, it turns out, lots of you do!

Remember in the olden days? Mum and gran would do most of their washing once a week and would always include a boil wash; there was no such thing as a mouldy door seal in their day.

Today, by contrast, we wash much more often at much lower temperatures, and this is is the reason why we have smelly, mouldy washing machines.

What Causes Black Mould to Appear On Door Seals

The root of the problem is a build up of bacteria inside your washing machine. The low-temperature washes create a cosy environment for the bacteria to grow and multiply. The residue left by this growth then allows the mould to grow.

Also, because of these low temperatures, residues from detergents and grease from your laundry remain in your washing machine creating the conditions for mould growth.

It's not only door seals that are affected. You will also find black mould build up in the dispenser drawer and housing where you add the detergent and softener.

You should be aware that these are the visible areas. You can see mould on your door seal every time you open the door. Your mouldy soap drawer is evident every time you fill it up. But what about the inside of the washing machine? If your door seal is mouldy then the inside of the washing machine drum, where you put your washing, will also be covered with bacteria and mould!

How do bacteria get Into my washing machine

Bacteria enters your washing machine mainly from our soiled clothes. Consider the following regular items of washing:

- soiled bed linen

- washable nappies

- dog fouling remains on clothes

- toilet mats

- pet's bedding and towels

- greasy overalls

While modern-day detergents are designed to wash at much lower temperatures, they won’t kill bacteria found on items such as listed above, in the way a boil wash does!

Consequences of Bacteria and Black Mould Build Up

Firstly, it is unsightly. Secondly, it could become a health hazard. Mould can also release spores which have the potential to irritate the lungs when inhaled.

If the build-up is excessive, it may be transferred to the laundry as you remove it from your washing machine. These marks may be stubborn to remove from clothing.

Excessive build up will become slimy and start to smell. If you leave your laundry in the washing machine drum for a length of time after the cycle has finished, you will notice that your clothes are smelly.

Sheared drum support shafts have become a real problem usually causing the washing machine to become uneconomic to repair. The residue of bacteria build-up is a jelly-like substance which fills the cavities in the drum support shaft arms. The support shaft arms are a metal alloy and acids created by bacteria enhance the corroding effect.

How can I treat and avoid bacteria in my washing machine

By merely replicating what we used to do years ago! Now and then put your washing machine through a service wash to help kill any bacteria build up.

How to keep your washing machine clean

How to keep your washing machine clean

Watch our DIY repair video on how to do a washing machine service wash

Why won’t my washing machine empty

This fault can be the cause of other washing machine problems such as the door won’t open, and the drum is not spinning.

Check for blockages

First of all, you will want to empty the water from the washing machine. Following the process outlined in the video below will also determine if you have a blockage, or not.

How to empty your washing machine that is full of water

How to empty your washing machine that is full of water

Watch our DIY repair video on how to empty your washing machine and check for blockages

Check the pump

If your washing machine isn’t blocked, then the fault will most likely be with the pump.

Possible faulty components that cause a washing machine not to empty

Faulty Pump

Once a blockage has been ruled out the most likely cause of a washing machine not emptying is a faulty pump.

How to replace a washing machine door handle

How to replace a washing machine door handle

Watch our DIY repair video on replacing a faulty washing machine pump.

Faulty Module

Although an uncommon fault, circuit boards do fail from time to time. It is best to seek the advice of a qualified technician if you suspec a faulty control module.